WNMG080408-DF PC8315T

SHITAEGER

NEK-WNMG81

Turning Insert

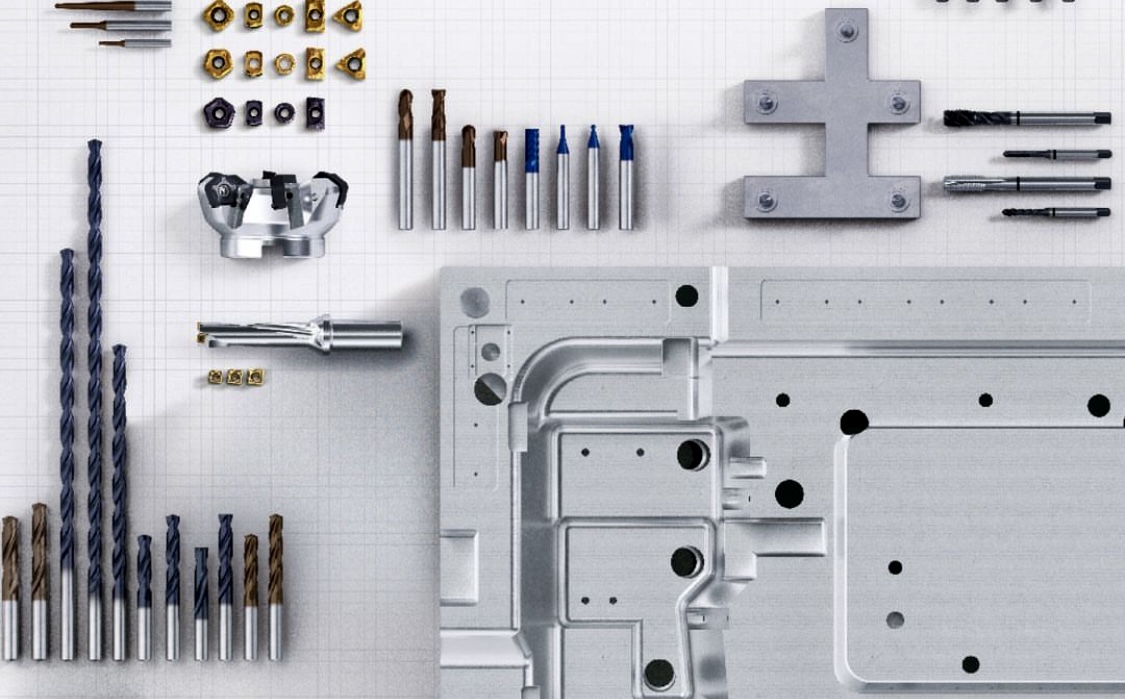

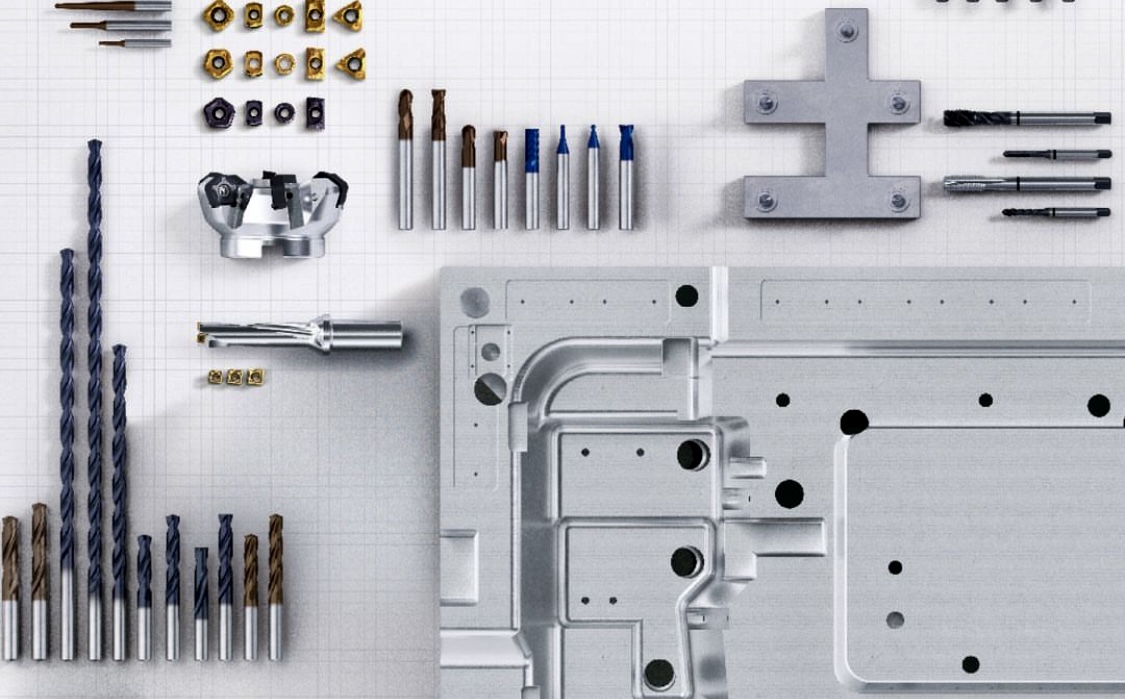

Automobile, machine tool, aviation, mould

10PCS/BOX

| Availability: | |

|---|---|

| Quantity: | |

1,Material

The material composition of the blade is a crucial factor that influences its performance and longevity. Typically, the blades are crafted from a variety of materials, each with its unique properties and advantages. One of the most common materials used in the fabrication of blades is cemented carbide, which is often a combination of tungsten and titanium alloys. This alloy is known for its exceptional hardness and durability, making it ideal for cutting through tough materials. Another prevalent material is high-speed steel, which is favored for its ability to retain its hardness at high temperatures and its excellent wear resistance.

1. ** Carbide ** : with high hardness, high wear resistance and high red hardness, suitable for processing a variety of cast iron, non-ferrous metals, alloy steel and so on.

2. ** High speed steel ** : with good toughness and wear resistance, suitable for processing various steel and cast iron parts, especially in the need to withstand greater impact and vibration of the occasion.

3. ** Ceramic ** : high hardness, good wear resistance, suitable for high-speed cutting and processing of high hardness materials, such as hardened steel, stainless steel, etc.

2.Features and advantages:

High speed steel turning tool has the advantages of good toughness and sharpening.

The carbide turning tool has the characteristics of high hardness and good wear resistance.

Ceramic turning tools have higher hardness and heat resistance, but brittleness is greater.

The turning tool adopts the cemented carbide welding blade, therefore, the price is low, and the service life is above two times than that of the ordinary welding blade turning tool.

3.Application

Turning blade is widely used in various lathe machining, including outer round turning, inner hole turning, end turning, thread turning and so on. Specific application scenarios include but are not limited to:

1. ** Machinery manufacturing ** : Used for processing various mechanical parts, such as shafts, sleeves, gears, etc.

2. ** Automotive industry ** : Used for processing engine cylinder block, crankshaft and other auto parts.

3. ** Aerospace ** : Used for processing aircraft engine blades, turbine discs and other high-precision and difficult parts.

4. ** Mold manufacturing ** : Used for processing mold cavity, core and other key parts.

Cemented carbide indexable inserts chip-breaking groove is the most prevalent method to control chips.

1,Material

The material composition of the blade is a crucial factor that influences its performance and longevity. Typically, the blades are crafted from a variety of materials, each with its unique properties and advantages. One of the most common materials used in the fabrication of blades is cemented carbide, which is often a combination of tungsten and titanium alloys. This alloy is known for its exceptional hardness and durability, making it ideal for cutting through tough materials. Another prevalent material is high-speed steel, which is favored for its ability to retain its hardness at high temperatures and its excellent wear resistance.

1. ** Carbide ** : with high hardness, high wear resistance and high red hardness, suitable for processing a variety of cast iron, non-ferrous metals, alloy steel and so on.

2. ** High speed steel ** : with good toughness and wear resistance, suitable for processing various steel and cast iron parts, especially in the need to withstand greater impact and vibration of the occasion.

3. ** Ceramic ** : high hardness, good wear resistance, suitable for high-speed cutting and processing of high hardness materials, such as hardened steel, stainless steel, etc.

2.Features and advantages:

High speed steel turning tool has the advantages of good toughness and sharpening.

The carbide turning tool has the characteristics of high hardness and good wear resistance.

Ceramic turning tools have higher hardness and heat resistance, but brittleness is greater.

The turning tool adopts the cemented carbide welding blade, therefore, the price is low, and the service life is above two times than that of the ordinary welding blade turning tool.

3.Application

Turning blade is widely used in various lathe machining, including outer round turning, inner hole turning, end turning, thread turning and so on. Specific application scenarios include but are not limited to:

1. ** Machinery manufacturing ** : Used for processing various mechanical parts, such as shafts, sleeves, gears, etc.

2. ** Automotive industry ** : Used for processing engine cylinder block, crankshaft and other auto parts.

3. ** Aerospace ** : Used for processing aircraft engine blades, turbine discs and other high-precision and difficult parts.

4. ** Mold manufacturing ** : Used for processing mold cavity, core and other key parts.

Cemented carbide indexable inserts chip-breaking groove is the most prevalent method to control chips.

Phone: +86-18868651999

Email: eden0906@nekkk.com

Add: ROOM 1-2, 17TH FLOOR, 9TH BUILDING, NO.35, XINGHAI ROAD(NORTH), GAOXIN DISTRICT, NINGBO CITY, ZHEJIANG PROVINCE, CHINA