NEK

1

1

40cr 20crmnti

Car

1 Box- 1 P

CNC Tool

| Availability: | |

|---|---|

| Quantity: | |

Select the appropriate machine tap material, you need to consider the following factors:

Processing material

Soft materials (such as aluminum, copper) : For soft materials such as aluminum and copper, high-speed steel machine taps are more suitable. High speed steel has good toughness, can prevent the tap from breaking when processing soft materials, and can maintain good cutting performance during processing, and process good quality threads.

- Ordinary steel (such as carbon steel, alloy steel) : in most cases, high-speed steel machine taps can meet the demand. However, if there are high requirements for processing efficiency and tap life, cemented carbide material can also be considered. The wear resistance of cemented carbide can reflect the advantages in the processing of ordinary steel, which can effectively reduce the wear of the tap and improve the service life.

- High hardness materials (such as hardened steel, stainless steel) : hard alloy material is a better choice. Its high hardness can smoothly cut the surface of high-hardness materials, and in the processing process, the wear of the cemented carbide tap is relatively small, which helps to ensure the processing accuracy.

Processing mode

- High-speed cutting: If it is processed on a high-speed cutting machine tool, the cemented carbide tap is more suitable. Because cemented carbide has good thermal hardness, in the case of high temperature cutting, it can still maintain good cutting performance, and high-speed steel may reduce hardness at high temperatures, affecting the life and processing quality of the tap.

- Normal speed cutting: high-speed steel taps are fully capable of normal speed cutting. Its toughness can play an advantage in this case, can withstand a certain cutting force, and the price is more reasonable than the cemented carbide tap.

Processing environment

- Humid environment: If the processing environment is relatively humid, it is easy to cause the tap to rust, then the coated high-speed steel tap with better rust prevention performance is a good choice. The coating can insulate the tap from contact with humid air to a certain extent and extend the service life of the tap.

- Environment with corrosive substances: When there are corrosive substances in the processing environment, it is necessary to choose a material with good corrosion resistance. For example, some cemented carbide taps or specially coated high-speed steel taps can effectively resist chemical corrosion and ensure the normal use of taps.

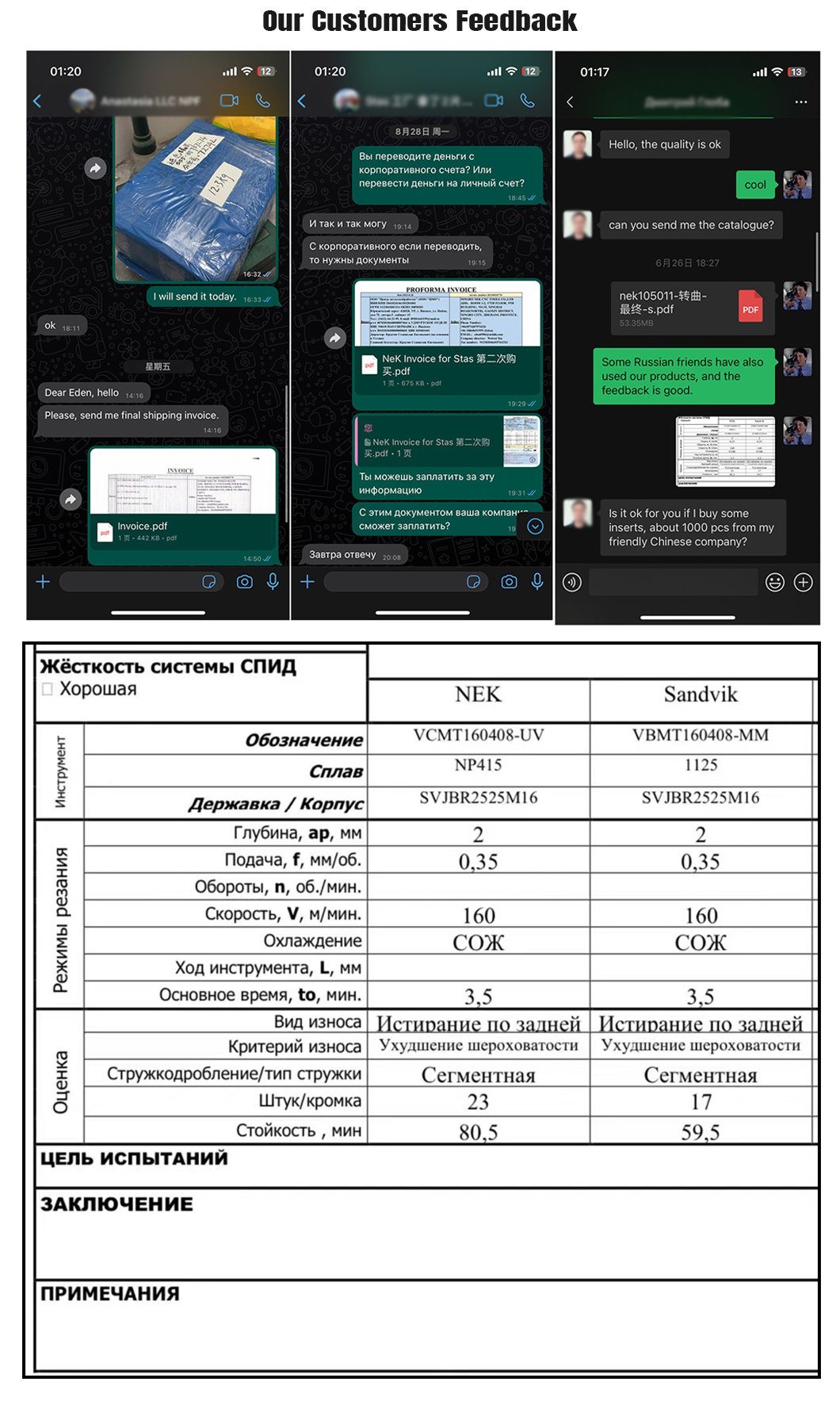

How many years has your company had production experience? Our company was established in 2000 and was reorganized in 2007 as NeK CNC tools Co.,Ltd. After so many years, our company has a team of terminal customers and a team of dealer customers. At present, we are one of the largest distributors of YG in China. We also have our own invested factory and our own OEM brand(NeK and SHITAEGER for insert)We are famous in Ningbo City, Zhejiang Province, China.

Do you have alloys for stainless steel, for titanium? Our brand inserts' advantage is good at process steel and stainless steel. Recently, we have also introduced inserts for process titanium alloy materials.

That is the Minimum order quantity?

300~500 pcs. Foreign customers need to bear the freight by themselves.

That is the Production time? We have a large stock of all the common styles on the market. A small number of special types' inserts need to be re-counted after communication.

What is the volume of plate production per month and per year? 50 million pcs/year

Do you have a representative office in Russia? Not yet.

Can you make production of special items? Yes.

do you have warehouse? In China.

lead time for new items? At present,High speed land transport for 15-20 days

Air transport for 7-8 days

Select the appropriate machine tap material, you need to consider the following factors:

Processing material

Soft materials (such as aluminum, copper) : For soft materials such as aluminum and copper, high-speed steel machine taps are more suitable. High speed steel has good toughness, can prevent the tap from breaking when processing soft materials, and can maintain good cutting performance during processing, and process good quality threads.

- Ordinary steel (such as carbon steel, alloy steel) : in most cases, high-speed steel machine taps can meet the demand. However, if there are high requirements for processing efficiency and tap life, cemented carbide material can also be considered. The wear resistance of cemented carbide can reflect the advantages in the processing of ordinary steel, which can effectively reduce the wear of the tap and improve the service life.

- High hardness materials (such as hardened steel, stainless steel) : hard alloy material is a better choice. Its high hardness can smoothly cut the surface of high-hardness materials, and in the processing process, the wear of the cemented carbide tap is relatively small, which helps to ensure the processing accuracy.

Processing mode

- High-speed cutting: If it is processed on a high-speed cutting machine tool, the cemented carbide tap is more suitable. Because cemented carbide has good thermal hardness, in the case of high temperature cutting, it can still maintain good cutting performance, and high-speed steel may reduce hardness at high temperatures, affecting the life and processing quality of the tap.

- Normal speed cutting: high-speed steel taps are fully capable of normal speed cutting. Its toughness can play an advantage in this case, can withstand a certain cutting force, and the price is more reasonable than the cemented carbide tap.

Processing environment

- Humid environment: If the processing environment is relatively humid, it is easy to cause the tap to rust, then the coated high-speed steel tap with better rust prevention performance is a good choice. The coating can insulate the tap from contact with humid air to a certain extent and extend the service life of the tap.

- Environment with corrosive substances: When there are corrosive substances in the processing environment, it is necessary to choose a material with good corrosion resistance. For example, some cemented carbide taps or specially coated high-speed steel taps can effectively resist chemical corrosion and ensure the normal use of taps.

How many years has your company had production experience? Our company was established in 2000 and was reorganized in 2007 as NeK CNC tools Co.,Ltd. After so many years, our company has a team of terminal customers and a team of dealer customers. At present, we are one of the largest distributors of YG in China. We also have our own invested factory and our own OEM brand(NeK and SHITAEGER for insert)We are famous in Ningbo City, Zhejiang Province, China.

Do you have alloys for stainless steel, for titanium? Our brand inserts' advantage is good at process steel and stainless steel. Recently, we have also introduced inserts for process titanium alloy materials.

That is the Minimum order quantity?

300~500 pcs. Foreign customers need to bear the freight by themselves.

That is the Production time? We have a large stock of all the common styles on the market. A small number of special types' inserts need to be re-counted after communication.

What is the volume of plate production per month and per year? 50 million pcs/year

Do you have a representative office in Russia? Not yet.

Can you make production of special items? Yes.

do you have warehouse? In China.

lead time for new items? At present,High speed land transport for 15-20 days

Air transport for 7-8 days

Phone: +86-18868651999

Email: eden0906@nekkk.com

Add: ROOM 1-2, 17TH FLOOR, 9TH BUILDING, NO.35, XINGHAI ROAD(NORTH), GAOXIN DISTRICT, NINGBO CITY, ZHEJIANG PROVINCE, CHINA